e-works successfully organizes No. 5 manufacturing delegation to Germany again

October 28, 2016, Wuhan—Chinese Digital Enterprise Portal e-works successfully organized No. 5 “Exploring Industry 4.0” delegation to Germany again from October 15 to October 24 2016. During the stay, more than 10 executives from well-known Chinese manufacturing enterprises and software vendors together visited 9 world-class manufacturers and software vendors in Germany.

The delegation arrives on October 16, Sunday. On the morning, they visited Heidelberg, one of the most famous cultural cities in Germany.

Delegation members’ group photo

Wine Tasting Dinner

Listening to BPM expert’s report

Mr. Markus Hass and Mr. Cheng Shizhen talking fundamentals of ultrasonic welding

On October 18, the delegation visited Sap Headquarter. Mr. Andreas Hube, SAP China Business General Manager received them with fluent Chinese and took them to the Inspiration Pavilion. Later in SAP21 Office Building Mr. Bernhard Meyer SAP Industrial Machinery and Parts Industry Solution Manager Bernhard Meyer introduced visitors SAP’s integrated solution, their understanding of Industry 4.0 and IoT, and best practice.

SAP expert lecturing

In the afternoon, the delegation came to the Audi A8 assembly plant in Neckarsulm, Germany. It is Audi’s second production base in Germany with models of A4, A5, A6, A7 and R8. Audi guide introduced their plant layout and vehicle production progress through a short film.

Guide introducing Audi history

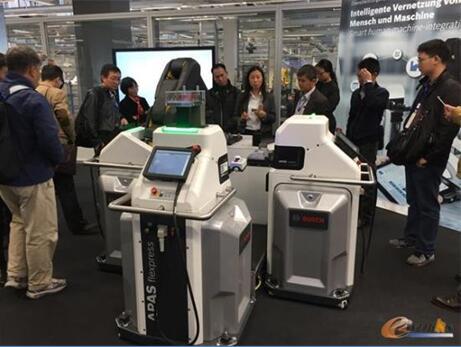

Bosch APAS working demo

Later the day, they visited one of the world’s biggest machine tool building company—DMG MORI in Pfronten, Germany. Mr. Zhang Shaoxian, DMG MORI Greater China Sales Manger introduced DMG MORI’s profile, product series, research and development, and CELOS software. Mr. Zhang guided the visitors to workshop, machining workshop, and CNC machine center.

LASERTEC 65 3D Machine tool in Hybrid Manufacturing Machining Center

On October 20th, we came to visited Glashütte Original near Dresden. Every watch of Glashütte Original has to go through 3-7 years of research and development before production. 3D CAD, CNC techniques are used in the production nowadays but the most important process and assembly is still finished by hand.

Glashütte Original’s old watch making equipment

On the morning of October 21, they came to the Phoenix Contact in Bad Prymont. Mr. Frank Schewe introduced their Industry 4.0 practice and understanding and took them to the assembly workshop. The whole workshop is automatic and has a RFID and bar code-based tracking system.

Group photo before Phoenix Contact

On October 21, they came to the SYCOR Headquarter. SYCOR is a well-known industrial software vendor, providing services for IT consulting and software assets. It is also an implementation service partner of SAP and Microsoft.

Mr. Marco talking SYCOR’s ERP implementation theory

After all the investigation and exploration schedules, the delegation members had a three-hour discussion to summarize their learning and understanding of intelligent manufacturing and Industry 4.0. In the future, e-works will continue to provide more opportunities for manufacturing enterprises to go overboard to learn and experience advanced manufacturing.

Summarize and discussion

More information please visit:http://www.e-works.net.cn/report/201610germany/industry.html