e-works Successfully Concludes 10th Delegation to Japan, Unlocking the Code of Lean Manufacturing

From June 22 to 29, 2025, e-works successfully organized the 10th Japan Lean Manufacturing Study Tour in 2025. Through factory tours, cutting-edge technology lectures, and in-depth seminars, the delegation members gained a comprehensive understanding of the latest developments in Japan's manufacturing industry, as well as cutting-edge trends and practical applications of smart manufacturing.

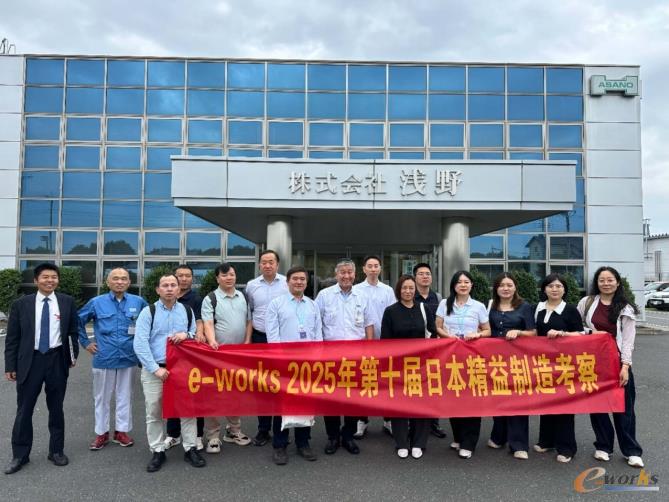

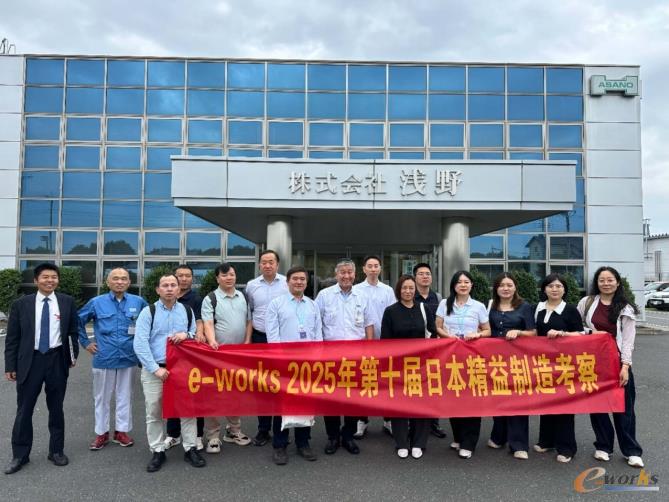

This tour marks the 42nd international delegation organized by e-works. Led by Dr. Huang Pei, CEO of e-works, the delegation visited global leaders including SMC, Makino, Yokogawa Electric, Asano, Suzaki, Zuken. They also attended a special lecture on lean production practices and lean digital transformation hosted by the Japan Management Association, delving into the secrets behind Japan's sustained leadership in manufacturing.

Smart Manufacturing Pioneers: Integrating Lean Production with Smart Manufacturing Practices

The first stop was the headquarters and Shimotsuma Factory of SMC, a global leader in pneumatic control components and systems. The delegation was warmly received by senior executives. Founded in 1959, SMC, as a core supplier of pneumatic components, holds approximately 40% of the global pneumatic control market share. Focusing on product lightweighting, intelligence, and green manufacturing processes, SMC's Air Management System (AMS), wireless systems, and Bernoulli-type suction cups inspired the delegation deeply.

Group photo at SMC headquarters

Makino, a leading global machine tool manufacturer, specializes in vertical and horizontal milling machining centers, renowned for high quality and precision. The delegation visited Makino's Atsugi Factory, including the casting machining FMS system, assembly workshop, application technology center, and electric spindle manufacturing plant. Makino highlighted applications of new technologies such as automatic chip breaking, high-speed spindle machining and testing, and ultra-precision mirror milling, allowing the delegation to deeply experience Makino's dedication to product quality and the integration of automated manufacturing with craftsmanship.

Group photo at Makino

The delegation visited Yokogawa Electric's Kofu Factory, a global leader in measurement, industrial automation control, and information systems. As one of Yokogawa's largest production bases in Japan, the Kofu Factory develops and manufactures field devices, wireless field equipment, oscilloscopes, spectrometers, and other measuring instruments. Mr. Wang Dong, Deputy General Manager of Yokogawa Electric China, warmly received the delegation. During the visit, the delegation gained detailed insights into Yokogawa's advanced factory energy management system, various products including pressure transmitters and sensors, and the clever implementation of error-proofing in the assembly process, leaving a deep impression on the members.

Visiting Yokogawa's Kofu Factory

Founded in 1953, Asano specializes in manufacturing trial parts for new automotive and motorcycle models, producing over 10,000 types of components annually, covering almost all external automotive parts. The company has adopted the Amoeba Management System to achieve "full employee participation in management." During the visit, the delegation observed advanced technologies such as carbon fiber composite and aluminum alloy composite molding parts, aluminum-steel composite parts formed by special riveting processes, and magnesium alloy stamping parts. This visit showcased the professional survival and development strategies of small and medium-sized Japanese manufacturing enterprises.

Group photo at Asano

Founded in 1953, Suzaki is a small automotive parts enterprise, with approximately 70% of its products supplied to Toyota-related companies. Despite its small scale, Suzaki has achieved rapid development by implementing the Toyota Production System (TPS) to build an efficient production system. Mr. Mikio Washizaki, the former chairman, warmly received the delegation and explained Suzaki's lean production practices. The delegation learned in detail about the company's Kanban management, extensive application of Pokayoke (error-proofing) in stamping and forging workshops, and the implementation of SMED (Single Minute Exchange of Die). Continuous promotion of lean production, improvement of manufacturing processes, and realization of human-machine collaboration have enabled Suzaki's sustained development.

The delegation visiting Suzaki

Digital Engine: Cutting-Edge Exploration in Industrial Software

B-EN-G, a well-known Japanese enterprise management software and service provider, began ERP implementation in 1991 as an SAP partner and developed its independent ERP product, mcframe in 1996. Through supporting system implementation for numerous Japanese manufacturing enterprises, B-EN-G has accumulated extensive expertise, applying experience from large domestic and international projects to system construction to meet the automation and systematization needs of manufacturing enterprises. Its independently developed mcframe is currently used by over 1,000 enterprises.

Group photo at B-EN-G

Founded in 1976, Zuken is a renowned software vendor specializing in the development, sales, and support of PCB/MCM/Hybrid and IC packaging design software in the EDA industry. With a turnover of 38.47 billion yen and an operating profit of 4.8 billion yen in the 2024 fiscal year, Zuken has maintained steady growth for three consecutive years. Zuken highlighted the CR 8000 PCB design software, features and typical cases of its electrical and electronic PDM software, and demonstrated the application of Autonomous Intelligence technology in automatic PCB routing, which greatly inspired the delegation.

The delegation exchanging ideas at Zuken

In-Depth Insights into Lean Production and Digital Transformation

At the headquarters of the Japan Management Association Group (JMAC) near Tokyo Tower, the delegation was warmly received by Mr. Hideki Nishioka, Director of China Business at JMAC, and attended a course on lean production practices and lean digital transformation. As a renowned Japanese consulting firm, JMAC has been committed to global enterprise management reform and talent development consulting services since its establishment in 1942. It has served enterprises in over 60 countries worldwide and began providing consulting services to Chinese enterprises as early as 1986. We gained insights into the unique charm of Japanese culture and management philosophy in global competition, and developed new perspectives on the path of enterprise lean production and digital transformation.

Group photo at JMAC headquarters

Heritage of Culture and History

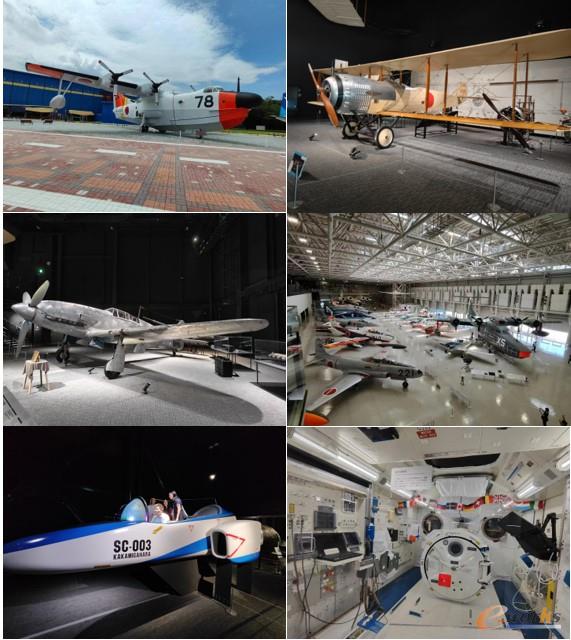

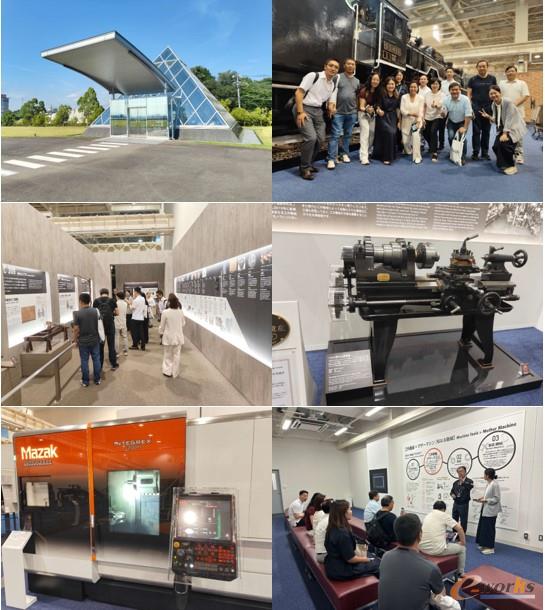

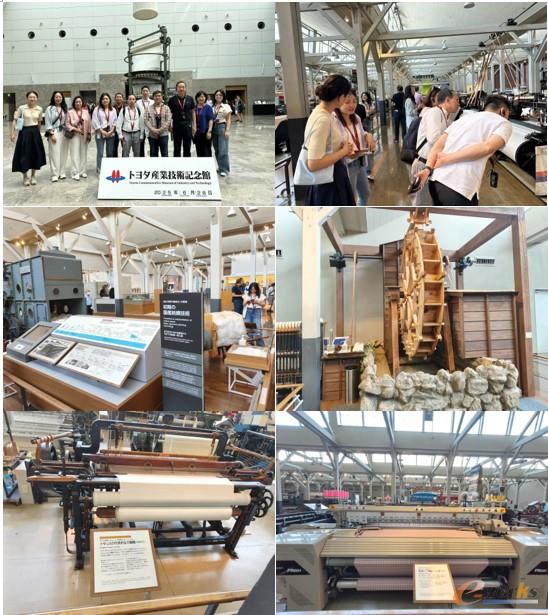

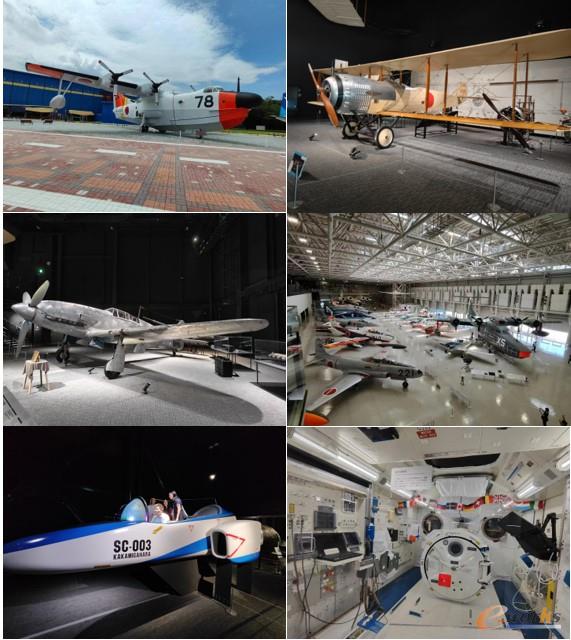

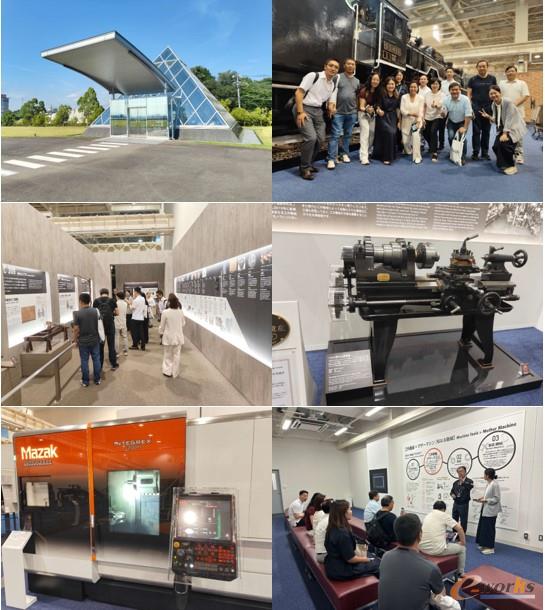

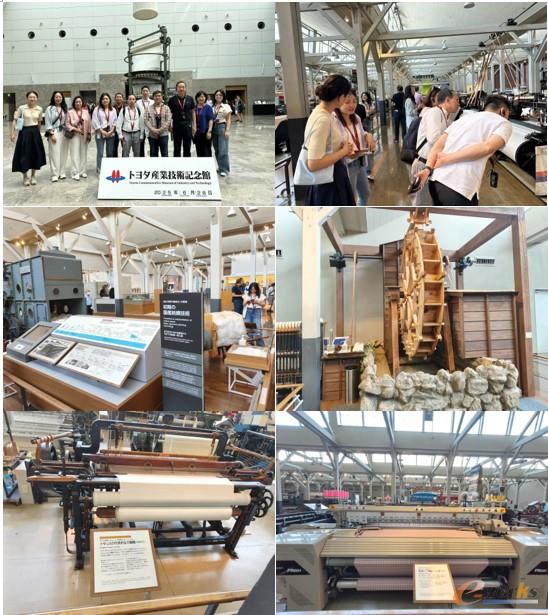

The delegation explored continuous innovation in Japan's aerospace sector at the Gifu Aerospace Museum, learned about advanced transformations in the machine tool industry at the Yamazaki Mazak Machine Tool Museum, and traced Toyota's "spirit of research and innovation" at the Toyota Commemorative Museum of Industry and Technology.

The Gifu Aerospace Museum, Japan's only museum dedicated to aviation and aerospace, is formerly Japan's earliest aviation base. The museum showcases the development history of aircraft from early models to modern airplanes and spacecraft. The museum also features a universe hall displaying Lunar and Mars exploration achievements, as well as real astronaut suits and aerospace consoles. The delegation gained a close understanding of Japan's aviation industry journey from imitation to independent research and development, and its continuous innovation in aerospace.

Gifu Aerospace Museum

The Yamazaki Mazak Machine Tool Museum, established in 2019 to celebrate the company's 100th anniversary, is an energy-efficient museum built approximately 11 meters underground, using geothermal energy to stabilize indoor temperatures. The museum exhibits numerous fully functional machine tools and representative industrial products manufactured by these machines. The delegation not only observed the structure of machine tools up close but also witnessed the actual production process of smart manufacturing units producing parts, experiencing the "new driving force" of technological innovation empowering the machine tool industry.

Yamazaki Mazak Machine Tool Museum

Operated by the Toyota Group, the Toyota Commemorative Museum of Industry and Technology was built on the site of the former Toyota Automatic Loom Works and opened in 1994 as the birthplace of the Toyota Group. Focusing on modern Japan's industrialization, the museum introduces Toyota's glorious history from textile and casting to the automotive industry, allowing the delegation to deeply feel Toyota's "spirit of excellence in research and innovation."

Toyota Commemorative Museum of Industry and Technology

Insights from Japan Lean Manufacturing Study Tour

During the one-week lean manufacturing study tour, through factory visits, technical lectures, and internal seminars, the delegation gained a profound understanding of the essence of Japanese manufacturing, the development and application of lean thinking (with the Toyota Production System as a key achievement) in different enterprises, and deeper insights into the management philosophy, product positioning, production manufacturing, and talent development models of leading Japanese enterprises. Delegates expressed great inspiration, noting many aspects worthy of learning and reference.

(1) Lean Thinking as a Cultural Gene

In Japan, the thinking of “lean” is not just a management method but a shared culture among all employees. In particular, "Kaizen" (continuous improvement) encourages participation from top decision-makers to ordinary employees. These cumulative incremental improvements form the cornerstone of Japanese enterprises' competitive success. In JMAC's lecture, Mr. Hideki Nishioka emphasized that Japanese enterprises value teamwork and collective wisdom, highlighting full employee participation and continuous improvement to drive lean production implementation across all processes.

(2) Adhering to Long-Termism

Japanese enterprises generally pursue long-term development strategies, committing to deep cultivation in specialized sector. Whether manufacturing leaders such as SMC, Makino, and Yokogawa, software companies like Zuken and B-EN-G, or consulting company like JMAC, all spend decades focusing on their niche markets. They pursue vertical expansion in their professional fields, striving to improve products and services, and build insurmountable competitive advantages through accumulated expertise.

(3) Pursuing Craftsmanship Spirit

Japanese enterprises deeply understand the philosophy of "Monozukui" (the art of manufacturing) and pursue excellence in craftsmanship. Taking Makino as an example, to create high-precision machine tools, Makino maintains demanding over the production environment: machining and assembly workshops achieve constant temperature and humidity, with temperatures precisely controlled at 23±1°C, and even ±0.4°C in assembly workshops, all regulated by real-time sensor systems. The choice of location near Mount Fuji is not only due to its high altitude, low temperature, and suitable humidity but also its solid granite foundation which provides unparalleled stability. Technologically, Makino skillfully integrates automation with craftsmanship: while using automated equipment for some scraping processes, it retains key manual scraping by senior craftsmen. This combination of technology and craftsmanship ultimately achieves sub-micron-level machine tool precision.

(4) Green and Sustainability: Fulfilling Corporate Responsibility and Commitment

Green and sustainability is not only a new direction for enterprise development but also reflects corporate responsibility to the environment and society. As an industry leader, SMC has always prioritized carbon reduction, designing more compact and lightweight products to reduce material usage and production time, and lower energy consumption. For example, regarding air blowing energy consumption (the largest energy consumer in air compressors), SMC's developed an air gun, which has increased peak pressure to over three times that of standard products while significantly reducing air consumption and operation time, resulting in an 87% reduction in carbon dioxide emissions. Yokogawa's Kofu Factory has adopted energy-saving measures since 1990, introducing and flexibly using energy consumption visualization systems. With "zero energy waste in production lines through IT," the Kofu Factory won the Trade and Industry Award of Japan Ministry of Economy.

(5) Excellence in Management Enables Vitality for SMEs

Excellence in management enables small and medium-sized enterprises to navigate economic cycles and maintain long-term vitality. For example, during the difficult period of Japan's economic bubble burst, Suzaki faced the crisis of bankruptcy. However, under the leadership of the previous chairman, the company implemented the Toyota Production System (TPS) and kept eliminating waste in production line. These efforts ultimately reversed the decline, allowing Suzaki to survive in fierce market competition. Asano introduced the Amoeba Management Model, fully trusting every employee, making operational status "transparent," and enabling all staff to participate in management, truly realizing "full employee participation in management" and promoting mutual growth of the company and individuals.

Currently, many outstanding Chinese manufacturing enterprises are actively expanding overseas, committed to international development. e-works will keep organizing international study tours on smart manufacturing, providing an effective path for China's manufacturing transformation and upgrading.

Smart Manufacturing Pioneers: Integrating Lean Production with Smart Manufacturing Practices

The first stop was the headquarters and Shimotsuma Factory of SMC, a global leader in pneumatic control components and systems. The delegation was warmly received by senior executives. Founded in 1959, SMC, as a core supplier of pneumatic components, holds approximately 40% of the global pneumatic control market share. Focusing on product lightweighting, intelligence, and green manufacturing processes, SMC's Air Management System (AMS), wireless systems, and Bernoulli-type suction cups inspired the delegation deeply.

Group photo at SMC headquarters

Makino, a leading global machine tool manufacturer, specializes in vertical and horizontal milling machining centers, renowned for high quality and precision. The delegation visited Makino's Atsugi Factory, including the casting machining FMS system, assembly workshop, application technology center, and electric spindle manufacturing plant. Makino highlighted applications of new technologies such as automatic chip breaking, high-speed spindle machining and testing, and ultra-precision mirror milling, allowing the delegation to deeply experience Makino's dedication to product quality and the integration of automated manufacturing with craftsmanship.

Group photo at Makino

The delegation visited Yokogawa Electric's Kofu Factory, a global leader in measurement, industrial automation control, and information systems. As one of Yokogawa's largest production bases in Japan, the Kofu Factory develops and manufactures field devices, wireless field equipment, oscilloscopes, spectrometers, and other measuring instruments. Mr. Wang Dong, Deputy General Manager of Yokogawa Electric China, warmly received the delegation. During the visit, the delegation gained detailed insights into Yokogawa's advanced factory energy management system, various products including pressure transmitters and sensors, and the clever implementation of error-proofing in the assembly process, leaving a deep impression on the members.

Visiting Yokogawa's Kofu Factory

Founded in 1953, Asano specializes in manufacturing trial parts for new automotive and motorcycle models, producing over 10,000 types of components annually, covering almost all external automotive parts. The company has adopted the Amoeba Management System to achieve "full employee participation in management." During the visit, the delegation observed advanced technologies such as carbon fiber composite and aluminum alloy composite molding parts, aluminum-steel composite parts formed by special riveting processes, and magnesium alloy stamping parts. This visit showcased the professional survival and development strategies of small and medium-sized Japanese manufacturing enterprises.

Group photo at Asano

Founded in 1953, Suzaki is a small automotive parts enterprise, with approximately 70% of its products supplied to Toyota-related companies. Despite its small scale, Suzaki has achieved rapid development by implementing the Toyota Production System (TPS) to build an efficient production system. Mr. Mikio Washizaki, the former chairman, warmly received the delegation and explained Suzaki's lean production practices. The delegation learned in detail about the company's Kanban management, extensive application of Pokayoke (error-proofing) in stamping and forging workshops, and the implementation of SMED (Single Minute Exchange of Die). Continuous promotion of lean production, improvement of manufacturing processes, and realization of human-machine collaboration have enabled Suzaki's sustained development.

The delegation visiting Suzaki

Digital Engine: Cutting-Edge Exploration in Industrial Software

B-EN-G, a well-known Japanese enterprise management software and service provider, began ERP implementation in 1991 as an SAP partner and developed its independent ERP product, mcframe in 1996. Through supporting system implementation for numerous Japanese manufacturing enterprises, B-EN-G has accumulated extensive expertise, applying experience from large domestic and international projects to system construction to meet the automation and systematization needs of manufacturing enterprises. Its independently developed mcframe is currently used by over 1,000 enterprises.

Group photo at B-EN-G

Founded in 1976, Zuken is a renowned software vendor specializing in the development, sales, and support of PCB/MCM/Hybrid and IC packaging design software in the EDA industry. With a turnover of 38.47 billion yen and an operating profit of 4.8 billion yen in the 2024 fiscal year, Zuken has maintained steady growth for three consecutive years. Zuken highlighted the CR 8000 PCB design software, features and typical cases of its electrical and electronic PDM software, and demonstrated the application of Autonomous Intelligence technology in automatic PCB routing, which greatly inspired the delegation.

The delegation exchanging ideas at Zuken

In-Depth Insights into Lean Production and Digital Transformation

At the headquarters of the Japan Management Association Group (JMAC) near Tokyo Tower, the delegation was warmly received by Mr. Hideki Nishioka, Director of China Business at JMAC, and attended a course on lean production practices and lean digital transformation. As a renowned Japanese consulting firm, JMAC has been committed to global enterprise management reform and talent development consulting services since its establishment in 1942. It has served enterprises in over 60 countries worldwide and began providing consulting services to Chinese enterprises as early as 1986. We gained insights into the unique charm of Japanese culture and management philosophy in global competition, and developed new perspectives on the path of enterprise lean production and digital transformation.

Group photo at JMAC headquarters

Heritage of Culture and History

The delegation explored continuous innovation in Japan's aerospace sector at the Gifu Aerospace Museum, learned about advanced transformations in the machine tool industry at the Yamazaki Mazak Machine Tool Museum, and traced Toyota's "spirit of research and innovation" at the Toyota Commemorative Museum of Industry and Technology.

The Gifu Aerospace Museum, Japan's only museum dedicated to aviation and aerospace, is formerly Japan's earliest aviation base. The museum showcases the development history of aircraft from early models to modern airplanes and spacecraft. The museum also features a universe hall displaying Lunar and Mars exploration achievements, as well as real astronaut suits and aerospace consoles. The delegation gained a close understanding of Japan's aviation industry journey from imitation to independent research and development, and its continuous innovation in aerospace.

Gifu Aerospace Museum

The Yamazaki Mazak Machine Tool Museum, established in 2019 to celebrate the company's 100th anniversary, is an energy-efficient museum built approximately 11 meters underground, using geothermal energy to stabilize indoor temperatures. The museum exhibits numerous fully functional machine tools and representative industrial products manufactured by these machines. The delegation not only observed the structure of machine tools up close but also witnessed the actual production process of smart manufacturing units producing parts, experiencing the "new driving force" of technological innovation empowering the machine tool industry.

Yamazaki Mazak Machine Tool Museum

Operated by the Toyota Group, the Toyota Commemorative Museum of Industry and Technology was built on the site of the former Toyota Automatic Loom Works and opened in 1994 as the birthplace of the Toyota Group. Focusing on modern Japan's industrialization, the museum introduces Toyota's glorious history from textile and casting to the automotive industry, allowing the delegation to deeply feel Toyota's "spirit of excellence in research and innovation."

Toyota Commemorative Museum of Industry and Technology

Insights from Japan Lean Manufacturing Study Tour

During the one-week lean manufacturing study tour, through factory visits, technical lectures, and internal seminars, the delegation gained a profound understanding of the essence of Japanese manufacturing, the development and application of lean thinking (with the Toyota Production System as a key achievement) in different enterprises, and deeper insights into the management philosophy, product positioning, production manufacturing, and talent development models of leading Japanese enterprises. Delegates expressed great inspiration, noting many aspects worthy of learning and reference.

(1) Lean Thinking as a Cultural Gene

In Japan, the thinking of “lean” is not just a management method but a shared culture among all employees. In particular, "Kaizen" (continuous improvement) encourages participation from top decision-makers to ordinary employees. These cumulative incremental improvements form the cornerstone of Japanese enterprises' competitive success. In JMAC's lecture, Mr. Hideki Nishioka emphasized that Japanese enterprises value teamwork and collective wisdom, highlighting full employee participation and continuous improvement to drive lean production implementation across all processes.

(2) Adhering to Long-Termism

Japanese enterprises generally pursue long-term development strategies, committing to deep cultivation in specialized sector. Whether manufacturing leaders such as SMC, Makino, and Yokogawa, software companies like Zuken and B-EN-G, or consulting company like JMAC, all spend decades focusing on their niche markets. They pursue vertical expansion in their professional fields, striving to improve products and services, and build insurmountable competitive advantages through accumulated expertise.

(3) Pursuing Craftsmanship Spirit

Japanese enterprises deeply understand the philosophy of "Monozukui" (the art of manufacturing) and pursue excellence in craftsmanship. Taking Makino as an example, to create high-precision machine tools, Makino maintains demanding over the production environment: machining and assembly workshops achieve constant temperature and humidity, with temperatures precisely controlled at 23±1°C, and even ±0.4°C in assembly workshops, all regulated by real-time sensor systems. The choice of location near Mount Fuji is not only due to its high altitude, low temperature, and suitable humidity but also its solid granite foundation which provides unparalleled stability. Technologically, Makino skillfully integrates automation with craftsmanship: while using automated equipment for some scraping processes, it retains key manual scraping by senior craftsmen. This combination of technology and craftsmanship ultimately achieves sub-micron-level machine tool precision.

(4) Green and Sustainability: Fulfilling Corporate Responsibility and Commitment

Green and sustainability is not only a new direction for enterprise development but also reflects corporate responsibility to the environment and society. As an industry leader, SMC has always prioritized carbon reduction, designing more compact and lightweight products to reduce material usage and production time, and lower energy consumption. For example, regarding air blowing energy consumption (the largest energy consumer in air compressors), SMC's developed an air gun, which has increased peak pressure to over three times that of standard products while significantly reducing air consumption and operation time, resulting in an 87% reduction in carbon dioxide emissions. Yokogawa's Kofu Factory has adopted energy-saving measures since 1990, introducing and flexibly using energy consumption visualization systems. With "zero energy waste in production lines through IT," the Kofu Factory won the Trade and Industry Award of Japan Ministry of Economy.

(5) Excellence in Management Enables Vitality for SMEs

Excellence in management enables small and medium-sized enterprises to navigate economic cycles and maintain long-term vitality. For example, during the difficult period of Japan's economic bubble burst, Suzaki faced the crisis of bankruptcy. However, under the leadership of the previous chairman, the company implemented the Toyota Production System (TPS) and kept eliminating waste in production line. These efforts ultimately reversed the decline, allowing Suzaki to survive in fierce market competition. Asano introduced the Amoeba Management Model, fully trusting every employee, making operational status "transparent," and enabling all staff to participate in management, truly realizing "full employee participation in management" and promoting mutual growth of the company and individuals.

Currently, many outstanding Chinese manufacturing enterprises are actively expanding overseas, committed to international development. e-works will keep organizing international study tours on smart manufacturing, providing an effective path for China's manufacturing transformation and upgrading.