e-works successfully organized the first Smart Manufacturing Delegation to UK

On July 14th, 2018, the first Smart manufacturing delegation to UK organized by e-works was officially kicked off. Led by Dr. Pei Huang, e-works CEO, all members of the delegation arrived in London after a long flight and officially opened a 10-day in-depth experience tour.

On the morning of July 16th, e-works delegation visited World’s leading semiconductor IP company ARM and its HQ. Over 95% of smart phones and tablets in the world are applying ARM architecture.

ARM company

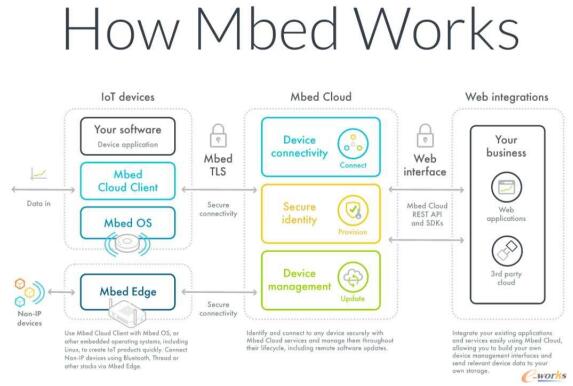

Experts introducing Mbed OS

How Mbed works

Group photo at ARM

In the afternoon, they went to globally well-known industrial software company AVEVA.

AVEVA

Meeting at AVEVA

Demonstration of VR technology

Group photo at AVEVA

On the morning of July 17th, the delegation visited the world’s leading metrology company Renishaw.

Renishaw was founded in 1973 and currently employs more than 4,000 people. The delegation experienced the application of Renishaw products, including CMM, machine tool probes, Equator, and metal additive manufacturing techniques applied in mechanical and dentistry, as well as in Raman spectroscopy and grating scale applications.

Renishaw products and applications

Group photo at Renishaw

On the afternoon, the delegation walked into BMW Mini Plant Oxford. Mini is a car brand that was launched by the British Motor Corporation and was held by BMW. The brand is a globally popular and compact small hatchback. It was launched on August 26, 1959 by the BMC. Within the history half a century, Mini has achieved a great success.

BMW Mini Plant Oxford

Mini Cars at exhibition center

ABB robot (from autohome.com.cn)

Assembly workshop (from autohome.com.cn)

5. Farnborough International Air Show

On July 18th, the delegation visited Farnborough International Airshow (FIA), the world’s second largest airshow to Paris Air Show. FIA hosts every two year and it is the 50th event. More than 1,500 machine and component manufacturers will participate in 2018, including the special exhibition area of Aerospace 4.0, which will showcase the Internet of Things, artificial intelligence, augmented reality, big data analysis, smart sensors, cloud computing, simulation and additive manufacturing. There’s also innovation zone showing various aerospace innovation practices.

Static airshow

Flying airshow

Exhibitors

Group photo

On the morning of July 19th, the delegation visited Autodesk Birmingham Innovation Center. Mr. Detlev Reicheneder Design and Engineering Global Business Development Director coming from German together with Mr. James Slater, Business Development Manager hosted our delegation.

Autodesk Birmingham Innovation Center

Mr. Detlev Reicheneder introducing the future of making things

Demo of a digital factory

Group photo at Autodesk

On the afternoon of July 19th, the delegation visited Romax Technology Center in Nottingham. Romax attaches great importance to this visit. Dr. Xiaobing Hu, Chief Commercial Officer, Mr. Carlo Bianco, Head of Commercial Operations, Dr. Chris Halse, Director of Global Engineering Services, and Dr. Michael Platten, Senior Software Product Manager, participated in the reception and introduced the development background of Romax , positioning and solutions.

Mr. Carlo Bianco, Head of Commercial Operations

ROMAX Technology Company

Visiting Romax

8. World's leading construction equipment manufacturer JCB

On the morning of July 20th, e-works delegation came to the JCB, world's top three manufacturers of construction equipment. With more than 70 years of innovation, JCB is the UK's largest industrial equipment manufacturer with 22 plants and 16,000 employees. The delegation visited JCB's VIP visitor center, welding, machining and assembly workshops, and R&D department. We fully experienced the continuous innovation of JCB and the enterprise spirit of to be the No.1.

JCB world headquarters

JCB products at exhibition hall

For more information about this delegation please visit: http://www.e-works.net.cn/report/2018england_rp/england.html