Will Onshape reshape global 3D CAD market?

On June 6th, 2016, I visited Onshape and interviewed Mr. John McEleney, the CEO of Onshape. I interviewed John for several times when he was the CEO of SolidWorks. I’m curiously to know the technology and business model of Onshape, and whether Onshape can really be the game changer of the global 3D CAD market, as the new generation cloud based CAD vendor. John mentioned during the interview that SolidWorks met the platform shift which is from DOS to Windows, and Onshape met another big platform shift which is from Windows to Could.

Mr. John McEleney, the CEO of Onshape

Pei Huang: Onshape has been a hotspot in CAD world recently, so why do you create Onshape?

John McEleney: The way people develop products is totally different from the way they did 20 years ago. Manufacturers have to meet unique requirement of customers, so they work on multiple versions of product to realize mass customization and collaborate with suppliers, thus, they have to send different version of the files back and forth, which is difficult to manage.

We feel that the design process has changed dramatically but the tools haven’t, so we decided to hit the reset button and built a whole new system, and synchronize product data management function with cloud based CAD.

We were inspired by Google Body, the first free3D model of the human body which has skeleton system, muscular system and circulatory system. It was a true interactive experience based on web browser. Mr. Jon Hirschtick said, it’s time that internet can support this. So, as a result, we built a native cloud based 3D CAD which can be used on any device, any web browser, and anywhere in the world. You need not worry about file version because there is no file any more, with all the information on the cloud based data base.

100% of CAD systems are desktop-based software. So, it’s clearly ready for transformation. It’s ready to be disrupted. That’s why we gather the team together about 3 years ago and raised the capital. Since then, we raised $169 million dollars. Last year, we tested our systems making sure things work. This year, we commercially released in January. It’s been used in over 150 countries and accessed nearly all over the world. By doing so, we think that is going to create a lot more opportunities for people to work on the right data at the right time and access anywhere. We think it’s a better way for people to work.

Onshape CAD is a very capable system and it allows me not just do viewing but actually modeling on any device and share with people. It’s a full CAD system.

Pei: What’s the difference between Onshape CAD and other cloud-based CAD software?

John: Other CAD is still file-based system. You still need to send files which mean you still have version problems. Onshape is different, it is data-based and there is no save button on Onshape. I can work in a browser, shut the laptop down and grab my laptop or my phone and log in and keep working, just like Gmail or any online system. It is just worked and saved as a transaction,so it is critical in terms of key differentiation.

Most recently, we announced FeatureScript. CAD system delivers the features like sketch, fillet, extrude and intersect. We deliver them to end users, but sometimes people may want to modify it. On Onshape, when users work in systems, they are actually creating code. It is called FeatureScript. You need not realize what’s behind. Onshape is an interpreter and that means you can create customer features. It’s not a macro language, and it’s very different. It is a first order features, so that you can truly build features for different manufacturers. It’s a very powerful capability.

Pei: How can Onshape help the users collaborate with each other to develop new product?

John: You can create a project team, and control the access permission of each engineer, for example, view, edit, and share. The team can work with the same document simultaneously, which can be an assembly, a part, or even a sketch. The team member can work together or off line. A team member can work offline and modify a part of an assembly, then, when he log in next time, he can merge his modification with the whole assembly. You can create multiple versions for the product, and if you make changes with a part and merge to the product assembly documents, the multiple version of assembly can be changed automatically, so, we have built PDM function into the system to enable the collaboration of the team.

Pei: How to keep product information confidential and secure?

John: In Onshape, you never send files around people. If I want to share something with you, the first thing happens is that I can choose the people I want to share with. If someone has full access, he can only do the viewing rather than editing. If I want to remove him afterwards, he will have no access. Since we never sending the file but sending a link, people have to log in and we can check their access. As a team, you can organize it by a team or a group, to make 3 members of the team to hold access to edit and comment or they only have access to view it. I can send link to outside people, but we can enforce and control with enterprise management services, says only shared to this email address or only share to these people. That’s enterprise-managed CAD. If using other systems, I can take that file and download it and email to anybody. There is no control. With Onshape, I can share to only these 30 people, so it’s far more secure.

Pei: Please introduce the pricing strategy of Onshape.

John: About the price, it’s 100dollarsper month for a professional version or free in product, but it’s exactly the same with the same functionality. The difference is the professional version has under limit private storage and private documents. The free version has a little bit storage and private documents. Anybody can make something private. The only person who can actually make it public and visible is the owner. When you hit your limits, you can buy the professional version. Then you have the enterprise management service on the top of that. That controls who can access what, when, where and how. You can choose to share inside the company or to certain suppliers.

Pei: Is all the computing done on the sever side?

John: Majority of the computing is done on the server, because each of these devices has GPUs. Laptops, ipads, iphones, all have graphical processers here, so a lot computing is done on local device. We do a lot to make the performance of these devices to work very well. We have a very clever way of sharing, updates with server. Most computing thing is done in the cloud.

`

Pei: Model-based Definition (MBD) is a hot topic in China now, do you have that function?

John: That’s going to be done initially. The bases for MBD is having a 3D model, so of course we do that. In terms of putting dimensions on the model, we can do that. In terms of trying to replace drawings with MBD, we think it’s a small portion of market, 8% market at best. On majority of market, it still needs engineering drawings. In longer term, MBD will be important but it still ways off in our opinion. I think cloud-based CAD is going to have greater adoption than MBD, and faster adoption. We fully expect to reach every engineer in the world. Some will use it a 1% of time, some will use it a 100% time.

Pei: What’s your future technology roadmap, for example CAM or CAE?

John: I think we are different. Till now, if you try to get access to a CAM application, you have to go through the reseller and depending on the reseller to support it. With Onshape, we put all sorts of applications in the app stores, and it is a pretty good way for the consumers to get applications directly. We think the buying process of consumers has changed. Our view is that we build the infrastructure and allow the application directly reach out to the consumer. We are not developing a CAM and analysis software by ourselves but we are building a strong eco-system.

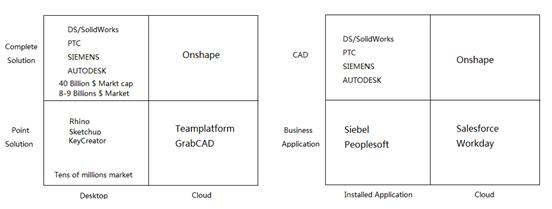

CAD Magic Quadrant by Mr. John McEleney

Pei: In terms of business target, what do you think of the CAD market?

John: With the platform shift, I think Onshape has great opportunity. We have the complete solution on the cloud. We hope to have the whole CAD market. In business application area, Salesforce and Workday are very good example. You can view the CAD magic quadrant above, that the vision we have, and we clearly see the future. So the big challenge is how we execute to get there. The pace we develop is very fast, every 3-4 weeks, we have a new release.

Pei: What’s your future plan in Asian Pacific area?

John: In China, now people can access through cad.onshape.com. We have lots of work to figure out to do and a team to build in China. Part of what we do this year is getting North America started. Once we do that, then getting something going on in Asia. We have to recruit a team and build out our China team. China is a very important market. It’s an opportunity for Chinese companies because Onshape is a very affordable solution for them. We have traditional Chinese version because we have a partner in Taiwan. We are working together to get Onshape launched there. We will have simplified version.

The meeting of Onshape software development team

Pei: Do you have a plan to go public in 2 or 3 years?

John: We have a long way to go before that, but our goal is to build a sustainable company that is a pillar in this industry. Much like SolidWorks, our goal is to have a very large significant presence. China is a very key part of that. That’s why we are being very deliberate when we do there. Our goal will be a very big sustainable company that does the acquiring, not getting acquired.

Mr. John McEleney (right) and Pei Huang (left)

John become the hero of Expendable2