Accurately managing the manufacturing operation process

Rockwell Automation is the world’s largest company dedicated to innovative industrial automation and information, making its customers more productive and the world more sustainable. Rockwell Software provides end to end solution in MOM (manufacturing operation management). Recently, I interviewed Bob Honor, VP of information solutions of Rockwell Automation in Shanghai. Greg Turner, Asia Pacific Director of Information Solutions of Rockwell Automation also joined the interview.

Huang Pei: Please give us a brief introduction of Rockwell Automation and Rockwell Software.

Bob Honor: Rockwell Automation was established 105 years ago in the United State, building electrical components. It has focused on manufacturing all 105 years and focused on manufacturing automation for recent 20 years. Rockwell came to China over 20 years ago. Rockwell has globalized its business corresponding to our moving to China 20 years ago.

Rockwell has been investing in manufacturing software over the last decade. To help manufacturing enterprise take advantage of IT application through our software development capability and our knowledge of manufacturing production processes, we formed a new information solution division called Rockwell Software. So, Allen-Bradley and Rockwell Software are two main brands of Rockwell Automation now. We have been developing MES, EMI (Enterprise Manufacturing Intelligence), and process automation & optimization technology over the last decade, etc. We are expanding this new group very quickly. It is the fastest growing part of Rockwell Automation. It belongs to Architecture and Software group of Rockwell which accounts for approximately 50% of our whole revenue. Another group is control product and solutions. Rockwell Automation is changing from a pure product provider to more and more a solution provider.

Mr. Bob Honor, VP of information solutions of Rockwell Automation

Huang Pei: Please share some views about the trend of automation industry.

Bob Honor: There are two forces driving automation in manufacturing. One is the need to globalize the business and be able to extend the supply chain around the world and also serve different markets as they emerge. The other is around sustainability, such as reduce of waste, use of resources more efficiently and less use of energy and water to produce. Manufacturers are paying more attention on getting real benefit and ROI from automation application. The other trend is called convergence. Communication, control, information and power technologies are coming together to build new products and services. We see a lot of benefits, and we see these technologies being used in an innovative way and allowing new applications to be developed in the automation area. So, convergence is becoming more and more important for driving our automation businesses in the future. In our demo room, you can see Ethernet is on every piece of equipment, even on power, and drive systems of motors. This technology did not exist five year ago. With Ethernet, you can now monitor the energy usage, you can send the commands down, and the system can respond faster.

Huang Pei: Please introduce the developing status of Rockwell Automation in Asia- Pacific region and especially Chinese market.

Greg Turner: In Asia-Pacific region, there are 3 important markets for us, China, India and South-Pacific for Rockwell information solution. We focus on specific industries with our solutions capabilities. In China we particularly focus on automotive, in which we have good business. We also focus on CPG and Tobacco industries. Our business in life sciences market has had a quite big expansion recently in China. It is driven by the need for compliance and GMP required by the government agency, such as FDA. We also have niche solutions in the oil & gas market as well, primarily around data management and process optimization, and we also have some specialized information solutions around water and waste water processing. Oil & gas, water and waste water processing are also our fastest growing market in China. Today there are about 1,500 water driven plants in China, and it is expected to grow to about 4000 plants by 2015, so it’s a huge expansion in that area. Another specialized area primarily in China which our solutions fit very well is manufacturing techniques for semiconductor, flat panel display and solar panel.

Mr. Greg Turner, Director of information solutions of Rockwell Automation

Huang Pei: Why and how did Rockwell Automation enter into MES market?

Bob Honor: First, there is a market opportunity. MES market is a growth part even in the decline of manufacturing in 2009. Second, I really think that it’s a natural evolution. The first reason why people use automation is to improve productivity. Our automation system already has the data, so that we can turn those data into information, operate on it, put it into the display, report, and make it visible, distribute around the company around the world. So, better decision can be made, and next level of improving productivity can be realized. So, it’s the natural extension from the business we have been doing for over 100 years. People use automation to improve the quality, to improve productivity, to lower the cost, so, information technology is the natural step to provide next level benefits.

Greg Turner: We primarily address MOM (manufacturing operation management), which is the real time aspect of all the manufacturing management issues. From the report of Gartner, ARC, etc, probably in the last 8 to 10 years, investment has started to turn from ERP as a transactional system to MOM. MES is only one product line in the solutions portfolio. In fact, our solutions include MES component, EMI component, data acquisition component, HMI, etc. We integrate these components on SOA platform and build MOM solutions rather than just MES. We can provide pure MES functions including 11 major application areas, but our solutions go beyond just MES, not only can our solution get data from shop floor factory devices, but can get data from any database from anywhere in the enterprise, including data from ERP system into management actions. We can also do process optimization using the data. So, we can provide an integrated platform based on manufacturing operation management approach rather than just MES approach.

Bob Honor: Rockwell has been involved in software since 1994. Bizware was released in 2001, which is our first MES kind of software. In 2005, Rockwell evolved to FactoryTalk platform. So, we have 15 years of development, both internal and by acquisition.

Huang Pei: What’s your view about the global MES market?

Bob Honor: Right now you can see a rush of many suppliers, but this status will be changed in the next 5 years. The market will be consolidated and only a few suppliers will dominate the market. It is just like today’s global ERP market.

Greg Turner: I believe there will be consolidation in the MES market. The number of suppliers will come down from more than 100 to only a few. I believe with our focus with convergence, and tying the platform devices together with multiple applications to build a MOM solution, Rockwell will be the leading supplier in that market.

Huang Pei: Some MES vendors just provide MES platform, but some other vendors just provide solutions for specific industries. In your view, which type of Rockwell belongs to?

Greg Turner: Both. We do have MES platform, and at the same time, we also can provide specific solutions to some industries on that platform.

Bob Honor: We focus on 6 industries with very specific applications on that platform. They are CPG (Commercial Packaged Goods), automotive, life sciences, chemicals polymers, biofuels and CMM (Cement/mineral/mining). We also have references in oil & gas industry and electronics.

Huang Pei: How many partners do you have to develop solutions based on that platform?

Greg Turner: There are different types of partners, including system integration partners, information solutions partners and enterprise solution partners, with several hundreds around the world. There are 3 high level enterprise solution partners in China, 3 in India, and 2 in South-Pacific regions, who are able to develop and implement Rockwell MOM solutions for the manufacturers.

Huang Pei: How could Rockwell software integrate other automation systems?

Greg Turner: We have connecters and drivers for all the automation systems, such as Siemens controllers, Mitsubishi controllers, etc. In fact, one of our value propositions is that if a customer is interested in applying our manufacturing solutions, we are not asking them to scrap their legacy system. We can use what they have and build the solution based on their legacy system. Not every vendor can do that.

Bob Honor: It’s called premier integration. There are tools of Rockwell information solutions allowing customers to integrate in a much easier and automated way.

Huang Pei: Can you summarize the feature and advantage of Rockwell Automation compared with the other MES vendors?

Bob Honor: The MES vendors could be divided into 4 types: automation suppliers, ERP suppliers, niche software suppliers and total solution providers. We have advantages against all types of vendors. The clearest advantage against ERP suppliers is we know manufacturing and our domain expertise are much greater. Compared with niche software vendors, obviously our broad scope and global presence could help any size of manufacturers to get competitive advantage. Against solution providers, the platform we have built is commercial and off the shelf software, but the total solution provider could only provide customized software, so that customers needs to buy tremendous maintenance and support. We meet fierce competition with other automation suppliers, but our unique advantage is that not only can we provide platform but also we have specific solutions for industry applications.

Greg Turner: There is an example. We worked with a manufacturing company who was looking for MES solution. Besides Rockwell, they also invited pure MES vendors. Not only does this manufacturing company compare the functions and features of MES software, but also they want to integrate MES with SAP ERP system. They finally chose Rockwell without the usual ‘battle’ of features because we have the expertise to tie the whole manufacturing processes into MES and integrate with SAP. We provide the platform with no requirement of scrapping their legacy systems.

Huang Pei: What’s your relationship with SAP and Oracle?

Bob Honor: We cooperate and compete with SAP and Oracle. On every installation and every project, we actually work very closely with SAP or Oracle. But we compete in selling MES solution, because SAP through MII, and ORACLE through manufacturing suite, they claim that they can provide MES solution and extend their solutions into manufacturing management. We have proven MES technology and we would love to have partnership with SAP and ORACLE.

Huang Pei: As I know, Dongfeng Automotive is a good reference of your MOM solution. What are the real benefits of your solutions for automotive company like Dongfeng?

Bob Honor: Automotive industry is very competitive. One of the key operation improvements we always provide for automotive customers is the ability to reduce their cycle times by keeping the inventories very low and allowing them to basically implement automating JIT (just in time) systems. Dongfeng is a perfect example where they replenish their inventory from outside suppliers less than 2 hours. We enable them tracking the production schedule and ordering schedule, and send signals to the suppliers to bring in material in a short period of time.

It is not possible without implementing MES system that monitor the order coming from business system and the actual consumption and usage going out from production and keep track the schedule what they actually need to build, because they need the right part there. They build different models and options of car by car bases, so they could not just bring in one type of BOM, because the BOM almost change car by car. Global automotive industry is so competitive that automotive manufacturers have to use MES system to keep agile. Automotive manufacturers face huge cost pressure, so, MES system gives the flexibility for them to produce what the customers exactly order and use accurate materials and parts. So, it brings very big benefit. It could really help automotive manufacturers shorten the cycle time and they need little inventory because the suppliers can send the right parts to right place at the right time. With MES system, they can reduce more and more cycle time and produce more and more cars with less and less cost. That’s one of the key areas of JIT application.

The automotive manufacturers have to look at schedules, planning, BOM, keep tracking inventory, and they need to know how the machines are running. Our MES systems help many automotive OEM companies to meet these requirements, including Dongfeng.

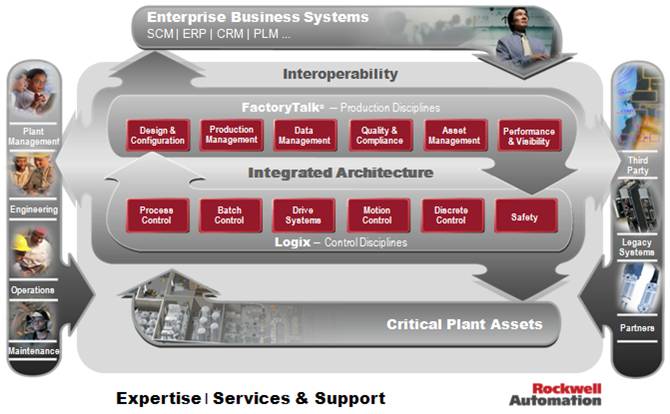

Huang Pei: Please introduce the architecture of FactoryTalk.

Bob Honor: The FactoryTalk Integrated Production and Performance Suite is made up of six distinct production disciplines, each with its own comprehensive and complementary set of applications. Through integration and interoperability, these modular product groupings address today's diverse plant information needs such as enterprise to plant-wide systems integration, MES, asset management, control system connectivity and HMI/SCADA, and in both modeling and programming environments.

Designed to meet ISA-95 industrial standards, the six disciplines will lower the total cost of ownership by offering a unique platform to pick and choose to develop industry specific solutions.

Plant Wide Control & Information Solutions of Rockwell Automation

Huang Pei: Do you have your own service team to deploy the solution or it is deployed by your partners?

Bob Honor: We use both ways. We have our own service team located in every country around the world. But many times the customers tell us whether they prefer us delivering the whole solution or they like to work with specified system integrators and let us train the partners. In some industries we choose to deploy by ourselves because we have expertise, and sometimes we have several partners locally available for the customers to use to deploy the solutions. In general, we deliver the whole solutions by ourselves for automotive industry.

Huang Pei: What is the most important MES function the customers care about?

Bob Honor: It depends on the industries. For example, compliance and documentation is the No.1 for pharmaceutical and biological industry. For automotive industry, it’s order scheduling. To keep machine continually running is the top care for customers in CPG industry. A survey we made recently showed that the most important business issues that tire manufacturers care are tracking and scheduling the intermediate parts. That is the reason why we find it is more and more important to build industry solutions based on our platform, with that solutions, we can easier to guide and meet the most important applications they need.

Huang Pei: Do you develop APS solution by yourselves or you integrate some other solutions?

Bob Honor: Mostly we use the third party’s APS solution or get from ERP. But we offer a finite capacity scheduling solution, but we typically don’t offer that first. Because to make finite capacity scheduling most effective, the customers need to optimize their production processes. The truly constrains in the production are dealt with by finite capacity scheduling, but we find many enterprises have very far to go to improve their individual machines performance before using finite capacity scheduling.

For the Chinese version, pleases visit:http://www.e-works.net.cn/interview/leader_274.htm

Recorder&Editor: Sophie Shi ss@e-works.net.cn