Semiconductor Outlook: What to Know and How to Plan

The supply chain’s uncertainty is daunting, but strategies are available to help companies prepare.

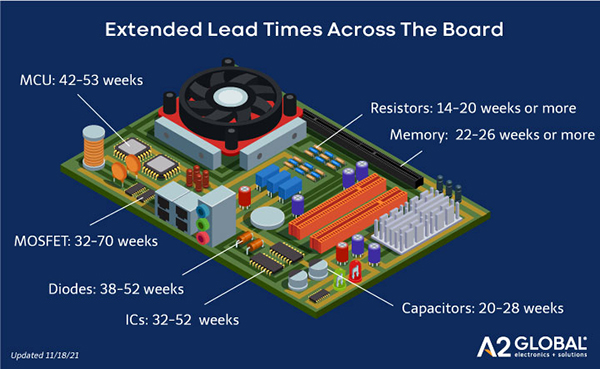

Component lead times as of November 2021 source: A2 Global

Shortage Drivers – Uncertainty and Limited Capacity

Uncertainty is a driving force behind the remarkable lead times we see for nearly every semiconductor. Uncertainty around COVID variants, unreliable power grids in key manufacturing countries, and sociopolitical influences like U.S. inflation are all potential supply chain disruptors. These uncertainties are compounded by a limited number of fabs (semiconductor fabrication plants) worldwide, making shortage mitigation and predictability much harder.

Manufacturing constraints and profitability priorities are also contributing to today’s crisis. Though there are calls to construct fabs in the U.S. to expedite chip production, fabs are costly and timely to develop and will not lend much, if any, relief in 2022 should these plans come to fruition. Semiconductor manufacturers are also forward thinkers, often prioritizing long-term technology innovation, scalability, and parts profitability over less profitable, legacy, and less popular part production. Their investments will go towards where they believe the greatest future demand will be rather than what is needed now, further limiting the electronic component supply chain.

With all of this in mind, 2022 will be a year of hedged bets and require decisiveness from businesses relying on access to electric components. There are three strategies that companies can utilize to best prepare themselves for the year ahead:

- Broaden vendor networks

- Build capacity for speed

- Benefit from varied supply chains

Broaden Approved Vendor Lists

Limiting the number of vendors a company sources its components from will be a hindrance in 2022 for several reasons. First, demand is already at an unsustainable rate with prices rising alongside it – companies are putting themselves in a weakened position if they only allow themselves to source from a smaller number of suppliers than are currently available. Second, companies cannot afford to miss out on parts they need over list-based technicalities – do not let perfect be the enemy of done in the face of a crisis and recognize when options are available. This will help with pricing and allocation options that will help weather next year’s storm.

Build Capacity for Speed

Prices and availability of components will continue to change rapidly in 2022, and delayed decision-making will result in higher prices paid and missed opportunities to source critical parts. Companies need trusted partnerships and relationships with their suppliers to make better decisions. While their vendor list can and should be robust to give themselves the best opportunity to source parts, having 2-3 trusted relationships can provide greater access to needed parts or insight that otherwise wouldn’t be available. This will help keep production lines moving rather than wasting time moving from supplier to supplier aimlessly.

Benefit from Varied Supply Chains

The status quo is forever disrupted by the chip shortage, but not necessarily for the worse. Glaring inefficiencies due to complacency with supply chain operations have come to light, forcing companies to get more creative with their buying strategies. This is a good thing and should not be looked at as a temporary measure in 2022. Recognize short-term and long-term goals, understanding how vendor decisions made today will impact tomorrow. A varied supply chain is a strategy that should have long been in place before the crisis, but current circumstances forced its emergence much faster than anyone was prepared for. Companies should use 2022 to holistically look at their supply chains, recognize what they can sustain long-term, and invest in new strategies.

2022 will not be a hopeless cause. Microcontroller units (MCUs) – the chips critical to automotive manufacturing – demand will continue to rise, but the shortage will not be as dire as in 2021. Discrete components will continue to see shortages and supply chain constraints for the majority of 2022. That said, everything is subject to change at some level, and companies must prepare for anything. By broadening vendor lists, increasing the capacity for speed, and utilizing varied supply chains, companies will be better prepared for the unexpected in 2022.

About the Author

Frank Cavallaro is CEO of A2 Global. With more than 25 years of successful leadership experience within the global technology distribution industry, Mr. Cavallaro is a seasoned executive who brings global market strategy and deep operating expertise to A2 Global. Frank has served as CEO of Converge (acquired by Arrow Electronics in 2010) and TotalTrax. Additionally, he has held senior executive roles at Arrow Electronics and NECX. With domain expertise in international management, selling strategies, sales organizations and global sourcing operations, Mr. Cavallaro is recognized as an industry leader within global technology distribution.