Body-in-white equipment manufacturer uses Tecnomatix to reduce the complexity of its working environment

Siemens PLM Software solution enables Dalian Auto to lay the foundation for developing a digital plant.

Gaining recognition

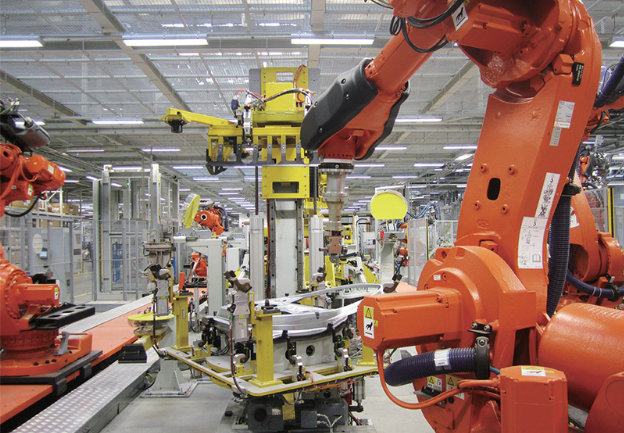

Dalian Auto-Tech Incorporated Corporation (Dalian Auto), founded in October 1990 and located in the Dalian High-Tech Industrial Zone in China, specializes in planning, designing, manufacturing and integrating systems for body-in-white (BIW) equipment. The company’s facilities cover an area of 100,000 square meters (m2) and a total floor area of 70,000 m 2. As the company continues to expand, its operating performance has risen year-after- year. Chen Yi’nan, general manager of Dalian Auto, says, “In 2014, we had a turnover of 1 billion yuan, and expect to further increase it to 1.1 billion yuan for the year of 2015.”

Using Tecnomatix to expand the market

A provider of system-integration equipment must be able to rely on extensive experience to provide its clients with customized production solutions. Additionally, it must take advantage of easy-to-use software tools, which not only leads to shorter design cycles and more accurate and applicable design solutions, but also to more efficient and reasonable utilization of resources as well as time and cost savings.

After conducting comprehensive studies in design, simulation and analysis functionality as well as user requirements and other indicators, Dalian Auto selected the Tecnomatix® portfolio from product lifecycle management (PLM) specialist Siemens PLM Software, marking the beginning of ongoing, in-depth cooperation between the two firms.

“Apart from the product, Siemens PLM Software’s extensive automotive experience, considerate after-sales services and timely training support also played an important part in our decision to establish a long-term partnership with them,” emphasized Qian Qiang, technology director at Dalian Auto.

In Dalian Auto’s implementation of projects for many prestigious automakers, including Volkswagen, BMW, Mercedes Benz and General Motors, the use of Tecnomatix provided functional advantages in many areas.

The Process Simulate solution in the Tecnomatix portfolio provides capabilities for design, analysis, simulation and optimization of factories, production lines and stations. It can be used for man-machine engineering simulations, which can effectively enhance control over operational feasibility at the early stage of product development. If extended to all stations, it can be used to analyze body fatigue in humans, as well as determine the best positioning and operating sequence for materials and equipment.

The Process Designer solution in the Tecnomatix portfolio is a comprehensive digital manufacturing system that connects all manufacturing disciplines – from process layout planning and design, to process simulation and verification, to manufacturing execution, to product engineering – thus facilitating overall innovation.

During the implementation of those projects, Dalian Auto realized a number of benefits by using these solutions, including:

Enhanced collaboration between multiple robots and related automation equipment, eliminating the complexity of the working environment

The ability to simulate robots’ working status in a real environment, and the availability of logical drive technology and integrated real robot simulation technology

The ability to use Process Simulate teaching boxes specific to different robots to enable precise offline programming (OLP), with simulation driven by actual control-logic-based events, making virtual commissioning possible

Improved efficiency and quality of robot OLP, thus saving time and cost of physical commissioning

Another extended function of events-based simulation, virtual commissioning, provides a more intuitive way to perform programmable logic controller (PLC) offline commissioning. The virtual commissioning of the entire assembly lines, Aufbau I and II, was finished even before entering the customer’s factory (including side inner plate point set packing, side out plate point set packing and repair welding of three PLCs). On some stations, Process Simulate was used to do the programming and commissioning of robots’ online programs. Since the virtual commissioning was ahead of the mechanical installation and commissioning schedule, after collecting and counting the working hours, it was found that the onsite commissioning time was reduced by 33 percent.

Dalian Auto has been relying on years of accumulated expertise, experience and technologies to meet the ever-changing production requirements of customers, and gaining recognition and trust by providing high-quality user services along the way. As a software provider, Siemens PLM Software has played an important role in Dalian Auto’s competitive development, and will remain its valued partner in helping it achieve future growth.

“As the number of projects increases, we will step up our investment in information technology, for which Siemens PLM Software is and, always will be, our favorite partner,” says Chen.

Delivering continuous innovation

The enterprise’s quick expansion, great strides in information technology, remarkable performances and prominent honors all make one wonder why such a capable enterprise has not gone public.

“We have thought about going public, but we have been thinking more about why and what next?” says Chen. “For us, gaining insights into the changing market, making good strategic deployments, continuously improving independent R&D (research and development) and optimizing production solutions are keys to building our competitive advantage.”

Going public is not the ultimate goal, but it is part of the process of an enterprise choosing its development direction. In an era in which the rise and decline of an enterprise sometimes happens overnight, Dalian Auto’s business focus and development orientation are particularly impressive.

Dalian Auto has more than 30 units of powerful computer numerical control (CNC) machines and CNC devices with high-end process and machining technologies, which help enable quality products and a monthly production capacity of 88,000 hours. The company has implemented an enterprise resource planning (ERP) system in the production process and has used it to manage and track work pieces, enabling the company to confirm production schedules and capacity in real time.

Dalian Auto has a complete quality control chain that covers everything from material warehousing, production and processing to completion of the final assembly, thus enabling the company to realize tight operational quality control of raw materials, purchased parts, riveting, machining, coordinate measuring machine (CMM) use, internal pre-acceptance and more.

In addition, Dalian Auto has a strong technology team that consists of more than 350 technicians, including planning experts and software engineers from Germany, robot engineers from the United Kingdom, R&D engineers from the United States as well as planners, simulation workers, designers, R&D personnel, technological platform engineers and electrical engineers from China.

“For an enterprise, customer satisfaction should be its pursuit, quality its lifeline, on-time delivery its branding, cost efficiency its key to survival, teamwork its source of strength and leanness, and excellence and innovation its source of development,” says Chen. “The excellence of an enterprise stems from the excellence of its products, while the excellence of its products is reliant on the excellence of its staff.”

To prepare for a new age of industry development known as “Made in China 2025” and Internet Plus, Dalian Auto has implemented more automation solution designs for improved efficiency as well as is making wider use of simulation technologies, constructing digital plants, developing enhanced collaborative protocols with Siemens PLM Software and pursuing even enhanced mutual trust and win-win relationships with customers.

Dalian Auto-Tech Incorporated Corporation (Dalian Auto), founded in October 1990 and located in the Dalian High-Tech Industrial Zone in China, specializes in planning, designing, manufacturing and integrating systems for body-in-white (BIW) equipment. The company’s facilities cover an area of 100,000 square meters (m2) and a total floor area of 70,000 m 2. As the company continues to expand, its operating performance has risen year-after- year. Chen Yi’nan, general manager of Dalian Auto, says, “In 2014, we had a turnover of 1 billion yuan, and expect to further increase it to 1.1 billion yuan for the year of 2015.”

Using Tecnomatix to expand the market

A provider of system-integration equipment must be able to rely on extensive experience to provide its clients with customized production solutions. Additionally, it must take advantage of easy-to-use software tools, which not only leads to shorter design cycles and more accurate and applicable design solutions, but also to more efficient and reasonable utilization of resources as well as time and cost savings.

After conducting comprehensive studies in design, simulation and analysis functionality as well as user requirements and other indicators, Dalian Auto selected the Tecnomatix® portfolio from product lifecycle management (PLM) specialist Siemens PLM Software, marking the beginning of ongoing, in-depth cooperation between the two firms.

“Apart from the product, Siemens PLM Software’s extensive automotive experience, considerate after-sales services and timely training support also played an important part in our decision to establish a long-term partnership with them,” emphasized Qian Qiang, technology director at Dalian Auto.

In Dalian Auto’s implementation of projects for many prestigious automakers, including Volkswagen, BMW, Mercedes Benz and General Motors, the use of Tecnomatix provided functional advantages in many areas.

The Process Simulate solution in the Tecnomatix portfolio provides capabilities for design, analysis, simulation and optimization of factories, production lines and stations. It can be used for man-machine engineering simulations, which can effectively enhance control over operational feasibility at the early stage of product development. If extended to all stations, it can be used to analyze body fatigue in humans, as well as determine the best positioning and operating sequence for materials and equipment.

The Process Designer solution in the Tecnomatix portfolio is a comprehensive digital manufacturing system that connects all manufacturing disciplines – from process layout planning and design, to process simulation and verification, to manufacturing execution, to product engineering – thus facilitating overall innovation.

During the implementation of those projects, Dalian Auto realized a number of benefits by using these solutions, including:

Enhanced collaboration between multiple robots and related automation equipment, eliminating the complexity of the working environment

The ability to simulate robots’ working status in a real environment, and the availability of logical drive technology and integrated real robot simulation technology

The ability to use Process Simulate teaching boxes specific to different robots to enable precise offline programming (OLP), with simulation driven by actual control-logic-based events, making virtual commissioning possible

Improved efficiency and quality of robot OLP, thus saving time and cost of physical commissioning

Another extended function of events-based simulation, virtual commissioning, provides a more intuitive way to perform programmable logic controller (PLC) offline commissioning. The virtual commissioning of the entire assembly lines, Aufbau I and II, was finished even before entering the customer’s factory (including side inner plate point set packing, side out plate point set packing and repair welding of three PLCs). On some stations, Process Simulate was used to do the programming and commissioning of robots’ online programs. Since the virtual commissioning was ahead of the mechanical installation and commissioning schedule, after collecting and counting the working hours, it was found that the onsite commissioning time was reduced by 33 percent.

Dalian Auto has been relying on years of accumulated expertise, experience and technologies to meet the ever-changing production requirements of customers, and gaining recognition and trust by providing high-quality user services along the way. As a software provider, Siemens PLM Software has played an important role in Dalian Auto’s competitive development, and will remain its valued partner in helping it achieve future growth.

“As the number of projects increases, we will step up our investment in information technology, for which Siemens PLM Software is and, always will be, our favorite partner,” says Chen.

Delivering continuous innovation

The enterprise’s quick expansion, great strides in information technology, remarkable performances and prominent honors all make one wonder why such a capable enterprise has not gone public.

“We have thought about going public, but we have been thinking more about why and what next?” says Chen. “For us, gaining insights into the changing market, making good strategic deployments, continuously improving independent R&D (research and development) and optimizing production solutions are keys to building our competitive advantage.”

Going public is not the ultimate goal, but it is part of the process of an enterprise choosing its development direction. In an era in which the rise and decline of an enterprise sometimes happens overnight, Dalian Auto’s business focus and development orientation are particularly impressive.

Dalian Auto has more than 30 units of powerful computer numerical control (CNC) machines and CNC devices with high-end process and machining technologies, which help enable quality products and a monthly production capacity of 88,000 hours. The company has implemented an enterprise resource planning (ERP) system in the production process and has used it to manage and track work pieces, enabling the company to confirm production schedules and capacity in real time.

Dalian Auto has a complete quality control chain that covers everything from material warehousing, production and processing to completion of the final assembly, thus enabling the company to realize tight operational quality control of raw materials, purchased parts, riveting, machining, coordinate measuring machine (CMM) use, internal pre-acceptance and more.

In addition, Dalian Auto has a strong technology team that consists of more than 350 technicians, including planning experts and software engineers from Germany, robot engineers from the United Kingdom, R&D engineers from the United States as well as planners, simulation workers, designers, R&D personnel, technological platform engineers and electrical engineers from China.

“For an enterprise, customer satisfaction should be its pursuit, quality its lifeline, on-time delivery its branding, cost efficiency its key to survival, teamwork its source of strength and leanness, and excellence and innovation its source of development,” says Chen. “The excellence of an enterprise stems from the excellence of its products, while the excellence of its products is reliant on the excellence of its staff.”

To prepare for a new age of industry development known as “Made in China 2025” and Internet Plus, Dalian Auto has implemented more automation solution designs for improved efficiency as well as is making wider use of simulation technologies, constructing digital plants, developing enhanced collaborative protocols with Siemens PLM Software and pursuing even enhanced mutual trust and win-win relationships with customers.